From the receipt to the expedition of materials, Tekna’s powders are kept in controlled environments at every stage of their transformation, consistent with many industry standard protocols.

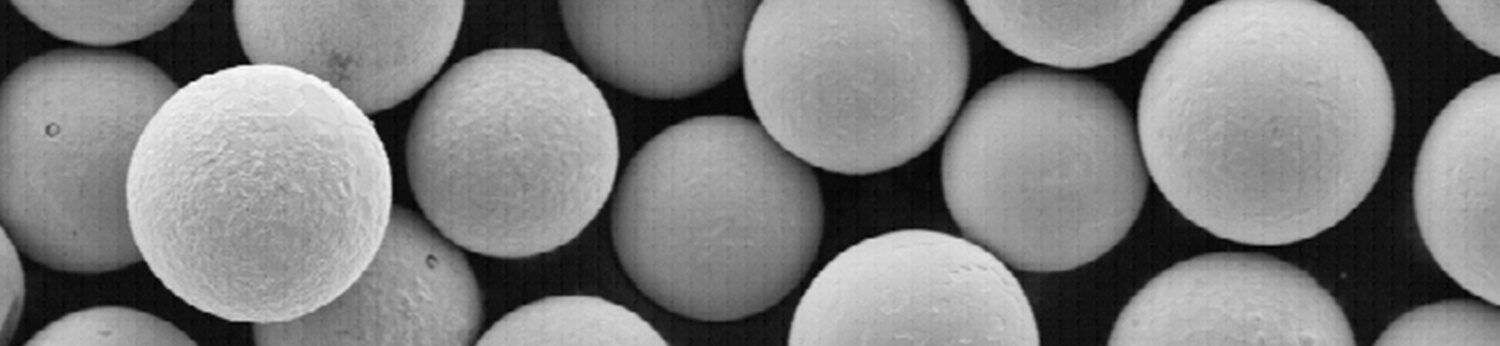

These manufactured powders are produced on an industrial scale, in a continuous process, having a high degree of sphericity, controlled particle size, high density (bulk and tapped), limited porosity (or gas inclusion), and minimal satellite content.

Our powders have a high level of purity, making them compatible with even the most demanding industrial applications such as:

Our facilities enable powder production in industrial quantities that meets the most demanding criteria.

Our approved process allows us to sieve and classify powders in a controlled and continuous operation.

Tekna’s spherical powders are recognized for their high sphericity, high density and high powder flow rate.

Due to our unique plasma process which doesn't require any consumables, the powders produced from our systems have a very high purity level